A day in the life of a bike designer

Ian Surra, director of Cannondale industrial design talks through a day in the R&D office in Freiberg, Germany.

I’m Ian Surra, the director of Cannondale industrial design. I wasn’t always the director; I started at Cannondale in 2014 as a junior designer in the US, in Wilton, Connecticut, in the headquarters there. I slowly worked my way through the organisation to end up where I am now, which is in Freiburg, Germany, leading a team of six other designers – and we think we have the best design team in the industry but probably everyone thinks that.

This is an R&D office, so it’s really just designers and engineers and product development… we keep all of the numbers people at a safe distance. Freiburg is a bike Mecca. I’ve only been here for two years – I came from the US – and there’s definitely a bit of a culture shock in being here, where in the morning, all the kids bike to school, and the young kids are being carried on the back of a bike or a cargo bike. That’s super inspiring; I think it’s a fantastic place to be – to centre you in this world of bicycles as transportation.

So I get up, I have some coffee and bike to work. I think everyone in this office bikes to work; there’s 28 of us and there’s never a car in the little parking lot – it’s all bikes, all the time.

I have a pretty short commute, 10-15 minutes, something like that. I’m always trying out one of our latest bikes […] we have a little fleet of office bikes that are mostly test-ride bikes and prototypes, things that we’re trying to vet or learn from.

People will try commuting on a bike a couple of times and they’ll have some feedback: “the suspension was a little soft here but it was really comfortable” or “I don’t know about the geometry, we could tweak the head tube a little bit” and then the team that’s working on the product can take all that feedback…that’s just the commute.

“It’s engineers, designers, product managers, all mixed around”

Our office is actually in a brewery. We’re tucked in the back in an old building that they no longer use and we built that up into our little R&D office. It’s a pretty intimate office and usually in the morning, there’s a little bit of making coffee and catching up before everyone gets to work. I’m not a super early morning person. It definitely takes me a little bit of time to get going – like a couple cups of coffee – but I’ll definitely be working by nine.

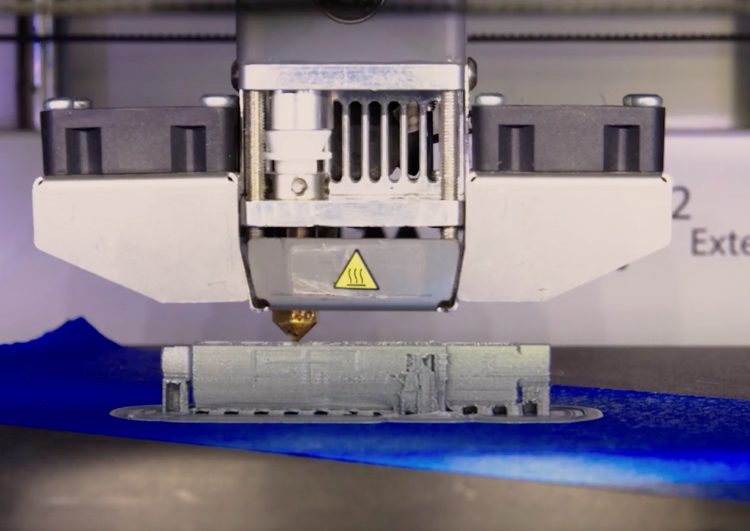

We have a pretty open office; it’s engineers, designers, product managers mixed around in a very long, narrow building. We have a fantastic workshop where we’re building prototypes and tinkering around as we’re developing things, and then some fabrication: we have a lathe, a milling machine and some 3D printers. It’s a pretty hands-on place. My title is director but we’re all pretty involved in everything, which is one of those nice things about being a relatively small office.

So, we might be the particular project team that’s working on, let’s say, an urban e-bike. There’s going to be an engineer and industrial designer and a product manager that are the core team.

If they’re really early in the project, they might be trying to figure out what the main scope of a bike will be: what are the experiences that we’re trying to create? What are the features that will help meet the needs of the rider? They might be hopping on a train to go to another city and do some research, meet with riders or talk with dealers and try to understand what the point of view of this particular rider will be.

If they’re a bit further along, they might be coming up with solutions to meet those needs. It could be something around rider comfort or around handling the batteries, or something purely aesthetic, like we just think that there’s an opening in the market for a really bold, beautiful bike.

And so the industrial designers are going to be pumping out sketches after sketches to figure out, what’s the angle going to be? What is the thing that’s going to really grab and entice people and make them fall in love with this bike?

We have this really wide and deep pool of knowledge about performance bicycles as well. So even though your urban e-bike doesn’t necessarily have to win a race, we still have 40 years of expertise in making a really light or really fast thing – or really understanding how a bicycle handles.

We have teams working on e-bikes, on urban bikes, road bikes, mountain bikes and e-mountain bikes. By having all these people in one place, we’re sharing a lot of knowledge with each other.

A lot of people are somewhat specialised. We try to develop the shared knowledge within a team so the urban group kind of sit near each other and they’re working together – and [it] will be somewhat consistent from project to project.

“Everyone pretty much takes lunch around noon… and goes for a ride”

On a nice day, you’ll see big groups of us go out for a ride and then come back and eat lunch. Today when it’s a little gloomy and rainy, more people are just going to be hanging around in the kitchen. I will probably walk around the corner to the bakery and get a sandwich. I might grab a couple of colleagues, see if someone else hasn’t brought a lunch.

As much as everyone would love to pretend that we’re not in meetings all the time, sometimes your afternoon is just meetings. Because it’s an international company, we work a lot with our colleagues in the US. For me especially, there’s quite a lot that happens in the afternoon when our time zones overlap.

There are also designers and engineers in the US; we’re working on projects together often we’ll have collaboration meetings where they might be reviewing the progress of a design and getting feedback from other groups. Mondays are always status meetings where everyone comes together and gets a bit of a snapshot of where all the projects are at.

“With bicycle design, the outward design and the function are the same thing”

I think one of the things that makes bicycle design unique and really quite interesting for industrial designers is that the outward design and the structure and the function are the same thing.

For a lot of goods, you design a shell, or you’re designing the things that the user will interface with, but all of the function is hidden. With bicycles, they are the same thing.

When you’re designing a bike frame, it has to be beautiful and has to invoke what we’re trying to invoke from an aesthetic sense. It also has to be structurally quite efficient and refined; it might need to be aerodynamic, or to hold a certain amount of cargo or be compatible with certain parts. All of that is in the same thing, so it requires these very close collaborative efforts between engineering, industrial design and product management.

No one can kind of just go off and make it on their own – or they can, but we’ll be missing quite a lot of what makes a great bicycle.

Engineering might send industrial design a clearance model of an aspect of the bike, and then we would spend the day either sketching on top of it, or designing in 3D, in CAD, and sending that back and forth. Or you go to the engineer, “I really want to have this line come in like that. That’s going to require us to push this surface out a little bit…” and then you’ll work it out.

Let’s say we get this part to a good point before the end of the day. We set it up to print out overnight in the 3D printer and in the morning, we see if it’s doing what we want it to do, maybe test fit it on a bike.

If it’s perfect, then then you might move on. But usually once you see something in real life – whether that’s a 3D print, the first samples from a mould, or the first tubes that have been made by the factory – the team will do a bit of review.

Everyone’s looking at it from different perspectives. Engineering might be measuring wall thicknesses and checking clearances; industrial design is looking at if it actually captures what I was trying to convey. Maybe we’re gonna need to bump that up or make this shadow more dramatic, or the opposite can happen where it looks tiny on my screen and it’s huge in real life.

And then at the end of the end of the day, I sit down and try to catch up on some emails. I text my wife I have time to see if there’s anything I need to grab on the way home, I bike home, lock up the bike, take the elevator up to the flat and my cat greets me at the door.

All images courtesy of Ian Surra and Cannondale. The transcript of this interview has been edited for sense and length.

-

Post a comment